|

| All strapped in and nowhere to go. |

Finally got a chance to take the Camaro to Peter Florance of PF Tuning fame for dynoing at Abacus Racing in Virginia Beach. If you recall, I installed the "new" 5.3 last year and got it started, but it was running really rich.

I waited until after Christmas to get a Tick clutch master cylinder because of clutch engagement problems. Between that and weather issues -- Peter said ideally, he tunes if the temps are 55 degrees or higher, and wouldn't you know it, southern Virginia was mid- to lower-40s for about eight straight weekends -- it wasn't until this weekend where Mother Nature finally cooperated. Who knew she could be a bitch even away from an autocross site!

The tow to the beach was thankfully drama free. This was really my first time towing with my new (now in possession for one year) 2017 Ford F-150. Rolling 87 octane and getting almost 15 MPG in sometimes crappy I-95/I-64 traffic.

|

| The new-to-me Ecoboost F-150 sipped almost 15mpg while towing. The Lightning maybe would get 15mpg not towing anything with the cruise control set at 55 on the interstate. And it needed 93 octane. |

I unloaded the car, we strapped it on the dyno, I swapped in new spark plugs with Peter's diligent supervision, and we went to work.

|

| Peter working under these conditions. |

Well, mainly I watched Peter work. He did a few easy runs under load around 2,500 RPM on the dyno to break things in.

The car had smoke from the exhaust and what appeared to be oil burning off the headers. I attributed it to brake fluid from bleeding the clutch eleventy times before installing the Tick master cylinder. The passenger side had oil seeping from the valve cover. The bolts weren't snug, but even after re-tightening, some oil still seeped out. I didn't address that leak since it wasn't that bad, but when I got back home, it seemed like the gasket wasn't entirely snug in the groove of the valve cover.

Anyway, the exhaust smoke, we presumed, was from first engine's residual oil lingering in the exhaust. I first started chasing issues early last year when it smoked badly and a small pool of oil formed under the exhaust exit. After repeated dyno runs, it was virtually smoke free.

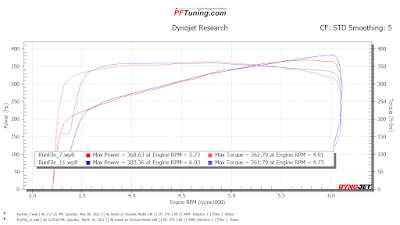

After break-in, Peter did four or five dyno pulls. With tweaking, the best run was 382 horsepower and 361 foot-pounds of torque. The old setup was 368/362. Peter attributed the increase to slightly cooler weather than last time, but, hey, more horsepower is still more horsepower! Figuring 12-percent to 15-percent drivetrain loss with a manual transmission (depending on who you want to believe on the internet), that's 427 to 439 horsies.

|

| The chart comparing 5.3 v1.0 and 5.3 v2.0. |

Also, the new setup seems to just be running better. Go figure with piston rings properly gapped! It runs smoother, and the O2 readings are virtually identical between both sensors right at startup. With the old 5.3, the O2 readout was inconsistent on the digital gauge -- one side would be bouncing around in the 11s while the other was in the 12s -- and wouldn't have similar readings until the engine temps warmed up. And even then, I was chasing my tail bugging Peter about it running mysteriously rich or lean, and he would send me new tunes to try.

|

| Cheapo fuel pressure gauge that attaches to an adapter on the fuel rail. Plenty of room! |

And some dyno video:

So things are looking ... good? Hopefully Project Whack-A-Mole doesn't have any major issues ... again.

First "event" on the schedule is a test-and-tune with the Chesapeake PCA at the Bowie Baysox Stadium. It's not a big lot but it's probably the shortest distance I will tow for an autocross -- about 20 miles. If something goes wrong with the car, the drive of shame won't be as brutal!

Comments

Post a Comment