I don't know where to start with this. I wish I had some great story about autocrossing and going for FTD and blowing up the engine or a mis-shift or something like that. But nothing. This car breaks while sitting in the driveway.

It started in December when awakening the car from an early winter slumber out trying take it for a spin (not literally) around the test loop. Cranked it to life, let it warm up and noticed smoke coming from the back of driver's side valve cover like oil was leaking onto the header.

First WTF moment.

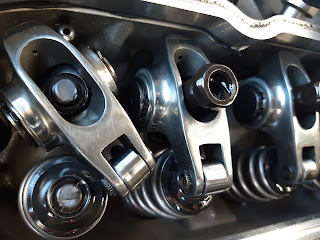

Thinking the valve cover gasket might be leaking for some dumb reason, I took the valve cover off to find this:

|

| A good name for a band would be Broken Rocker. But I don't like this music. |

That's from the No. 1 cylinder. The engine wasn't making weird noises or anything.

I went down an internet rabbit hole trying to figure out what rockers those were. They basically had a three-piece stud design -- stud through the rocker, a "nut" on top and a hex screw that tightened everything. After posting a picture on the Mullet Militia Facebook page (Thirdgen F-Body enthusiasts not a real militia so don't put me on some watch list), there were a few comments like, "WTF is up with those rockers?" Most people said they or others were using stock rockers with upgraded trunions for even applications approaching four figures in horsepower. Whether it be a 5.3, 6.0, 6.2 or whatever flavor of LS engine, OEM rocker arms were up to the task, especially for my mild power plant.

Just wanting to fix the fucking broken stud, I contacted my engine guy and apparently those rockers were so out the ordinary, he couldn't even remember what he installed. He stopped by my house with what he thought was a replacement rocker stud and produced a simple one-piece ARP stud that wasn't even close to working

Then he ghosted me.

I decided to get OEM-style LS rockers with upgraded trunions from Michigan Motorsports. They have always been great -- ordered a few things from them, and they always have fast service. They have a plethora of parts from moderate engines to higher horsepower applications.

Got the new rocker arms and since the 1.7 ratio was the same that was stamped on the fancy aluminum rocker arms I took out, figured it would just be a matter of replacing the rocker arms.

Nope. The pushrods that were in the motor were wayyyyy too short and wouldn't even keep tension with the rocker arms while going through the torqueing sequence Michigan Motorsports provided.

So I bought an adjustable pushrod tool (keep in mind all this isn't go-to-the-local-parts-store-and-be-back-in-5-minutes ... it's research stuff on the internet, order something, wait a few days for it to be delivered and hope everything works out for the best). Used the pushrod tool and calculated instead of the 7.2-inch pushrods that were in there I needed 7.3-inch pushrods. Ordered a set of those.

A few days later, installed the new pushrods, torque sequence again, buttoned everything up, fired the car and it ran like SHIT! No weird noises just chugged and billowed smoke.

Talked it over with Chris from work (who fabricottled the Aisin 5-speed and the exhaust) and he suggested stock-length (7.4-inch) pushrods, and I should be fine.

Back to ordering online, waiting a few days. Installed the new pushrods. Torqued the rocker arms in the correct sequence and procedure. Fired up. Ran exactly the same -- like SHIT!

Had thoughts about pushing the car off the cliff. Contacted a couple people who have been interested in the car and inquired if they still wanted to buy it. Thought better of it (I use that phrase loosely) and decided to punt and take it to a shop.

If you're scoring at home, we have leaking oil (from somewhere) and the No. 1 intake rocker with a busted stud that was "fixed" with whole new rockers.

What the shop diagnosed was this, second WTF moment:

|

| Valve spring on No. 6 that decided it was done with its life. |

On the No. 6 cylinder. On the opposite side of the engine where the troubles began.

I opted to take the car home and try and fix it myself. My reasoning was that if I had paid someone for a "built" engine and had all these problems, I could do work myself and save money instead of having other people work on it.

So I ordered new valve springs (again after careful research) and convinced Pete (who helped me put the engine in the car originally as well as get it fired up for the first time) to come over and install the new valve springs.

That went alright. Had already removed the passenger-side cylinder head to check for damage from a possible dropped valve (piston looked OK) and even installed the driver's-side valve springs with a mini compressor topping out at 20 psi to keep the valves closed.

Then I mentioned to Pete, "Oh yeah by the way, I forgot when installing the pushrods, the lifter felt squishy when pushing down on the pushrod on the No. 1 intake where the stud broke." I demonstrated, and he said, "Uhhhh, yeah that lifter is bad."

Off to the computer to scour the internet. Again back to Michigan Motorsports for a kit with LS7 lifters and head gaskets. Took that head off. I decided to take my time before putting the heads back on and clean the block up where coolant and gunk went down the threaded holes in the block for the head studs.

Then the third WTF moment:

|

| The entire No. 7 cylinder had enough of this bullshit. So have I, No. 7 cylinder. So have I. |

No. 7 cylinder. And I don't even know what happened here. Actually don't know what happened with anything. The engine did about 10 dyno pulls with zero issues. Drove it around the test loop a few times. A couple autocross runs (which were defeated because of things not related with the engine).

|

| The bad piston, scored up really good. |

However, all is not lost, at least for now. Luckily because of my job, a plan is coming together. We can rebuild it. We have the technology. We have the capabilities. We have another 5.3 all-aluminum block. Will it be better? Faster? Stronger?

Or maybe the fishing blog will get more attention. Or beg for co-drives.

Comments

Post a Comment